Rohacell® wing parts for UAVs and other airframe applications

Pronat Aerospace is an official Evonik stockist for Rohacell®

The following sheets are available from stock in various thicknesses

| WF – 51, 71, 110, 200 | |

| HF – 31, 51, 71 | |

| HERO – 110, 200 | |

| Available as standard sheet up to 1.25M x 2.5M and machined or shaped parts |

|

Pronat Industries is certified to AS9100D

Further information and data sheets on the full range of Rohacell® foams can be obtained from Pronat Industries at:

www.pronatindustries.com/product/rohacell/

or by contacting sales@pronat.industries.com

Rohacell® is a polymethacrylimide structural foam which is extensively used in the aerospace, marine, automotive and medical industries offering lightweight machined parts.

Rohacell® is a polymethacrylimide structural foam which is extensively used in the aerospace, marine, automotive and medical industries offering lightweight machined parts.

Pronat offers comprehensive manufacturing capabilities to produce core structures up to 1.25M wide and 2.5M long. In addition, we have suitable heating ovens and measuring devices to ensure consistent quality production. There are various Rohacell® grades available designed for specific applications, some of these are shown.

ROHACELL® HF is a closed-cell rigid foam with extremely low dielectric constants and particularly favourable transmission properties in the high frequency region, ROHACELL® HF has been specially designed for antenna applications. Applications range from miniature antennas in cell phones to large fixed ship-based and stationary antenna structures. Other advantages of ROHACELL® HF in such applications are its extremely fine cell structure that ensures minimal resin uptake, and problem-free compatibility with metallic facing materials due to the absence of corrosive effects. It is also used in Radoms and mammography plates.

PDF Datasheet

ROHACELL® WF is a closed-cell rigid foam which has been designed for use primarily in aerospace applications. It satisfies the usual industry requirements and also the MIL and CMS ROHACELL® WF rigid foam can be processed at pressures of up to 0.7 MPa and temperatures of up to 130°C. It is therefore highly suited for autoclave prepreg processing and all typical resin infusion after heat treatment, ROHACELL® WF can even tolerate curing temperatures of 180°C at a pressure of 0.7 MPa. ROHACELL® WF is easy to shape with CNC routing equipment.

PDF Datasheet

ROHACELL® HERO delivers the latest in materials technology for composite aircraft structures that are lightweight, durable over their lifetime and less expensive to produce. Offering excellent elongation at break properties, ROHACELL® HERO remains robust and durable for the lifetime of the aircraft.

No other core material offers such ease of processing in a wide variety of processes, including autoclave, resin infusion, RTM and VARTM. With heat resistance of up to 220 °C, processing or curing temperatures can be increased higher than other core materials allow (e.g., typical cure cycle at 180 °C/0.7 MPa acceptable). This results in significant reductions in total cycle time and faster part manufacturing.

ROHACELL® HERO is a recommended grade for core material in sandwich structures for aircraft wings, landing gear doors, radoms, vertical and horizontal stabilizers, ailerons and other areas subject to surface impact damage.

PDF Datasheet

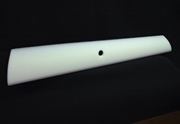

| Light weight propeller and section cores are produced in a selection of designs using Rohacell®aerospace grade foam. |

WINGS, FLAPS, AILERONS

|

|

|

|

|

|

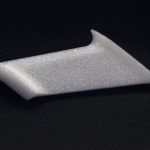

AIR FRAME PARTS

|

|

|

|

|

|

|

||

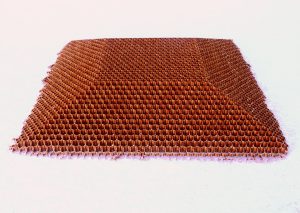

Nomex® Honeycomb sheet

DuPont™ Nomex® honeycomb composites helps to provide lightweight strength, stiffness, toughness, corrosion resistance, which bring high value-in-use to industries such as mass transportation, aerospace, construction, and marine shipping. For more than 30 years, the transportation industry has embraced Nomex® honeycomb composite made with DuPont™ Nomex® for its excellent strength-to-weight ratio, which assists to provide vital cost-effective benefits like energy savings and payload increases. Stiff, thin Nomex® sheet structures are used to help make strong, yet lightweight, honeycomb sandwich composite found in aircraft parts such flooring panels, interior walls, storage bins, exterior control surfaces, engine nacelles, and helicopter blades and tail booms. Nomex® honeycomb composites are also used in the construction of boats to help provide buoyancy that enhances speed.

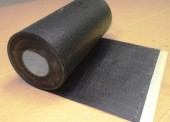

Composite & Pre-preg Materials

Pre-preg is a term for “pre-impregnated” composite fibers where a matrix material, such as epoxy, is already present. The fibers can take the form of a weave or non-woven and the matrix is used to bond them together. The matrix is only partially cured to allow easy handling, this B-Stage material requires cold storage to prevent complete curing. B-Stage pre-preg is always stored in cooled areas since heat accelerates complete polymerization. Composite structures built of pre-pregs will mostly require an oven or autoclave to cure.

Pronat has evolved several processing capabilities using composite materials including, bias sewing panels, and cutting and chopping coated B-stage fabrics from standard roll.

Graphite Wing & Frame Sections

Graphite sheet is used in the production of UAV panels and wings where additional mechanical strength is required.

Aircraft Window Stripping Masks

Paint removal masks are designed with pressure sensitive aluminum foil to safeguard aircraft windows by forming an impenetrable barrier against chemical stripping agents. To protect windows from paint overspray, these masks are made with aluminum, paper and crepe masking tape capable of withstanding temperatures up to 250°F. Stripping masks are pre-cut to window sizes with die-cut backing. Pressure sensitive adhesive provides holding strength without leaving any residue after use. Standard profile shapes are available for various aircraft including Airbus A320, Boeing 737, ATR 72 etc.