PRONAT Aerospace

- 3M Aircraft Interior ProductsMeet OEM specifications and aviation regulations with weight-saving, time-saving, strong-bonding interior solutions

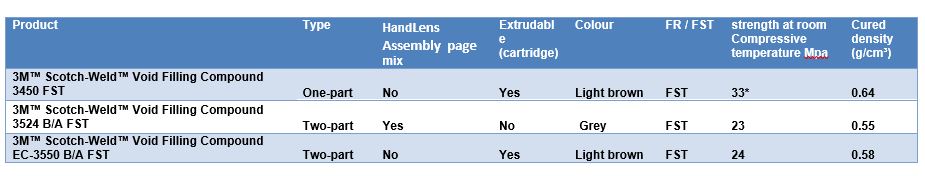

Edge and Void Fillers

Designed for filling mismatched areas and voids and reinforcing edges, 3M pumpable edge and void filling compounds combine high strength with industry-leading low density. Some meet FR per 14CFR 25.853 and others meet Flame Smoke Toxicity (FST) requirements:

Fillers include:

- 3M3450-FST

- 3M 3524

- 3M3460-HT FST

- 3M 3M3550 B.A.

More Information

Designed for filling mismatched areas and voids and reinforcing edges, 3M pumpable edge and void filling compounds combine high strength with industry-leading low density.

Featured Products 3M ™ Scotch-Weld ™ EC-3505 B/A FR

- Lightest machine-dispensable product available.

- Industry-leading combination of 0.44 g/cm 3 density with 2200 psi compression strength .

- Worklife: 60 minutes at room temperature Spend more time building and less time filling.

- Fully automated mixing and pumping for accelerated application process.

- Lightweight compounds with a variety of cure speeds and compressive strengths.

- Non-brittle property minimizes chipping and allows insert placement.

- Non-sag property reduces touch-ups and rework.

- FR and FST options

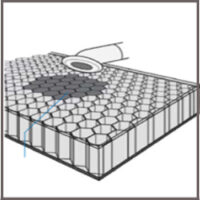

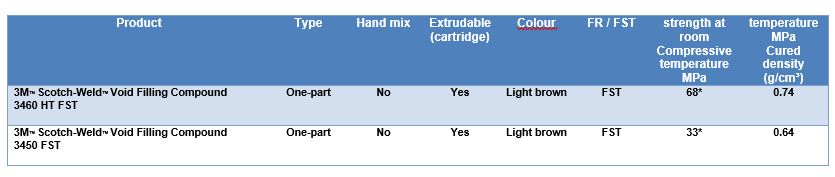

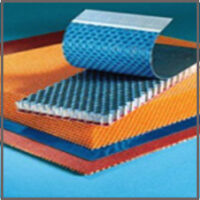

Core Reinforcement Compounds

Reinforce honeycomb and sandwich structures in load-bearing areas, such as overhead stowage compartments, partition walls, ceiling panels, galley and lavatory. These pumpable solutions save production time and labor costs — simply place cartridge in dispenser, add a nozzle and apply.

- Superior compressive strength.

- Excellent performance over a wide temp range.

- Some meet Fire Retardant (FR) per 14CFR 25.853 and others meet Flame Smoke Toxicity (FST) requirements.

More Information

- Fully automated mixing and pumping for accelerated application process

- Lightweight compounds with a variety of cure speeds and compressive strengths

- Non-brittle property minimizes chipping and allows insert placement

- Non-sag property reduces touch-ups and rework

- FR and FST options

3M™ Scotch-Weld™ Structural Adhesive Films

3M™ Scotch-Weld™ Structural Adhesive Film AF 163-2 is a thermally expanding films for gap filling. It provides excellent performance with easy-to-use shop handling properties. These adhesive films are available in a variety of weights and carriers to meet a range of needs without imposing excess material costs.

With high fracture toughness and peel strength, AF 163-2 provides a reliable, long-term bond suitable for composites, metals in solid panel and honeycomb sandwich fabrication. We also offer an unsupported version, which can be used for reticulation. It is also compatible with multiple substrates and primers. In addition, AF 163-2 exhibits excellent pre-bond humidity performance on composite substrates.

More Information

These thermally expanding films for gap filling, have a high performance over a broad range of temperature.

- Excellent shear strength even at elevated temperatures.

- Adhesive can be cured from 80°C up to 150°C

- Excellent pre-bond humidity performance on composite substrates.

3M™ Scotch-Weld™ Epoxy Adhesive Products

3M™ Scotch-Weld™ Epoxy Adhesive DP100NS is a non-sag, two-part, rigid epoxy adhesive offering a fast cure and machinability. It is a fast-setting epoxy that cures at room temperature to form a rigid bond. Non-sag formulation ensures adhesive stays where applied.

DP100NS works on a variety of substrates including metals, ceramics, concrete and wood. With a high shear strength it delivers strong, rigid performance, making it ideal for multiple applications in the electrical, general industrial, construction and consumer goods industries

Recommended Applications

- Attachment of various substrates that require permanency.

- General attachment applications in a variety of industries.

- Applications that require machining afterwards.