-

PRONAT Electronics

-

PRONAT Aerospace

-

PRONAT Medical

-

Production Capabilities

PRONAT Electronics

- Electrical Adhesive Tapes

Polyimide & Kapton® Tape

The use of a polyimide substrate, permits the availability of an adhesive tape that can be used short term at temperatures approaching 250°C as occurs during PCB wave solder processes. Other applications include paint spray protection, PCB masking and for electrical insulation during production. Many grades are available with a choice of silicone (most common) or acrylic adhesives. Substrate thickness is usually 25um although 13um and 50um are also common. Double sided and original Kapton® versions are available from stock.

Nomex® Adhesive Tape

Heat-resistant Nomex® aramid is used as a substrate for tapes requiring electrical insulation in high temperature environments. Thin backing provides minimum insulation build-up for wrapping of transformer conductors, motor coils and battery electrode insulation. Acrylic and silicone adhesive coated tapes are available in several thicknesses.

Polyester Film Tape

PET tapes are specified for electrical insulating applications requiring a thin, durable tape with high dielectric strength. They are resistant to chemicals, solvents, moisture and abrasion.

Polyester tapes come in a choice of pressure sensitive adhesives: rubber thermoset, acrylic, silicone and silicone/rubber blends to meet specific requirements:

- Acrylic for long term holding and clarity,

- Silicone for high temperature performance and clean removal,

- Specially-formulated rubber for resistance to plating chemicals. Many other variations of thickness, colours and surfaces are available. Yellow and clear are the most common tape used.

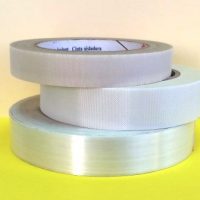

Glass Cloth Tapes

Glass cloth tapes offer excellent abrasion resistance and mechanical properties as well as high tensile strength and extreme temperature resistance. Service temperature ranges from -73°C to +260°C. Whilst highly conformable and flexible, their exceptional tensile strength make these tapes ideal for wrapping of electric coils, transformer windings and motor coil ends. Available in three adhesive types: class B (rubber thermoset), class F (acrylic) and class H (silicone)

Kraft and Crepe Paper Tape

Crepe paper tapes are used in numerous electrical applications for wrapping and masking. Typical usage is coil and transformer strip insulation where a tough and conformable tape is required. Natural rubber adhesive which provides good initial adhesion is the usual option.

Anti-Static Tape

Anti-static tapes (ESD) are used where there is a need to eliminate the effect of static in critical situations. These tapes are produced using polyester or a polyimide substrate which might be metallized. A conductive adhesive is also used to improve the ESD effect.

Electrical Insulation Die-cut Rolls

Many electronic manufacturers and electrical appliance producers, find it convenient to receive die-cut parts mounted on a roll with a split release liner. This method of parts delivery permits automation and ease of handling, reduces wastage and simplifies stock counting. Both dry and adhesive coated parts can be produced mounted on a roll.

Adhesive Masking Dots and Strips

Kapton® masking dots are used extensively for the masking of holes, connectors and other parts to protect these areas during the wave solder process. Polyester masking dots are used for protection during paint spraying. There are other masking dot materials available for various applications. Dots are generally produced 2,000 per roll with a split backing for easy release. Diameters range from 6mm increasing in 1mm increments up to 12mm, larger sizes can also be obtained. Strips and shapes are made to order. Masking dots and strips are produced with silicone adhesive coating.

Electrical Adhesive Tapes Chart

We provide below a comparative chart illustrating the many different types of electrical adhesive tape that Pronat offers. The majority of electrical tapes have either, silicone, acrylic or rubber thermosetting adhesive . All Stock of tapes are held in log form, we can therefore supply our customers with their preferred width of tape, with the best possible shelf life.

|

Pronat ref: |

Equivalent types |

Tape description |

Substrate thickness um |

Operating temp. |

Adhesive |

Characteristics – typical application |

|

P2100 |

3M56 |

25 |

130°C |

R/T |

Widely used in coil winding, available in yellow & clear |

|

|

P2101 |

CHR852 |

50 |

130°C |

R/T |

Heavy duty version of P2100 with additional mechanical and electrical strength |

|

|

P2102 |

3M1950F-1 |

25 |

130°C |

A |

High solvent resistance & dielectric strength, wide range of colours for component coding |

|

|

P2104 |

3M52 |

25 |

130°C |

S |

Thicker base film, suitable as mask in Powder Coating. |

|

|

P2103 |

50 |

130°C |

S |

Widely used as a mask in high temperature applications and as a splicing tape |

||

|

P2105 |

160 |

155°C |

A |

High tensile and dielectric strength coupled with good resistance to transformer oils |

||

|

P2206 |

P231 |

25 |

130°C |

R/T |

Double sided polyester tape. |

|

|

P2401 |

160 |

105°C |

R/T |

Easy to handle, conformable for coil finishing. |

||

|

P2500 |

3M11 |

Acetate cloth tape – class B |

160 |

130°C |

R/T |

Coil wrapping with excellent conformable tape |

|

P3100 |

CHR-G569 |

Glass cloth acrylic tape – class F |

110 |

155°C |

A |

Ideal for coil wrapping and holding where tear and abrasion resistance are required |

|

P4100 |

3M69 |

Glass cloth silicone tape-class H |

140 |

180°C |

S |

Coil wrapping with class H temperature rating |

|

P4400 |

50 |

180°C |

A |

Widely used in electrical motor manufacture for good temperature resistance. |

||

|

P4401 |

Hot Air levelling tape |

200 |

180°C |

S |

Excellent resistance and clean removal in solder levelling processes |

|

|

P4001 |

3M5413 CHR2345-1 |

25 |

180°C |

S |

Kapton® polyimide tape, specified for aerospace and used extensively for electronic applications and as a wave soldering mask. |

|

|

P4102 |

3M1205 P70100 |

25 |

155°C |

A |

Kapton® polyimide tape used where a permanent bond is required with good dielectric strength and solvent resistance. |

|

|

P4103 |

3M92 |

25 |

180°C |

S |

The most common polyimide tape, used extensively for electronic applications and as a mask in wave soldering. |

|

|

P4109 |

CHR-K104 |

13 |

180°C |

S |

Extra thin polyimide tape, used for specialist electronic & avionic applications. |

|

|

P4104 |

H-50 CHR2345-2 |

50 |

180°C |

S |

A high temperature resisting tape, using 50 μm polyimide film. It is also used as a mask in the wave solder process where an improved tensile strength and electrical resistance are specified. |

|

|

P4205 |

CHR-K100 |

25 |

180°C |

S |

D/S version of P4103 used for high temperature mounting and laminating applications |

|

|

P4106 |

3M5419 CHR-K290ESD |

25 |

180°C |

S |

Designed to provide excellent electrostatic dissipation when used as a PCB wave solder mask. Provides clean and safe removal after processing. |

* A=Acrylic R/T= Rubber thermosetting S= Silicone