-

PRONAT Electronics

-

PRONAT Aerospace

-

PRONAT Medical

-

Production Capabilities

PRONAT Electronics

- Gasketing & Sealing

Gasketing materials which maintain excellent resistance to compression set, exhibit high resiliency, good vibration damping and shock absorption. Die-cut parts continue to perform after constant and repeated deflection. Components prevent leakage and maintain their integrity no matter the internal or external environment.

Poron® Polyurethane Foam

PORON® Microcellular Urethanes offers the flexibility required by designers to solve their mechanical cushioning requirements. From gasketing and sealing to performance cushioning. High performance urethanes are used to seal out water and dust, absorb impact, and provide long-term gap filling. Typical applications include handheld devices, electronic equipment, interior and exterior automotive uses and medical devise production.

PORON products incorporate these highly reliable benefits:

- Excellent compression set resistance which enables durable, long-term performance for gasketing, sealing, and cushioning.

- Low-outgassing and non-fogging, containing no plasticizers or residual chemicals to contaminate the device. The material will not become brittle and crumble and is non-corrosive to metal.

- Inherently flame retardant without the use of additives. Many of the materials meet flammability requirements of UL HBF and MVSS 302.

- Good chemical resistance

- Easy to fabricate, die-cuts cleanly and works with a broad range of adhesives

- Broad range of formulas and thicknesses from 0.012″ to 0.500″ (0.43mm to 12.7mm)

PORON® 4701-30 – Very soft, easily compressed for use where flexibility is a key requirement. Standard available thickness range from 0.53mm.

Download data sheet: PORON_4701-30_Very_Soft data sheet

PORON® 4701-40 -Soft material for a wide variety of applications. Standard available thickness range 0.79 mm to 12.7mm

Download data sheet: PORON_4701-40_Soft_data sheet

PORON® 4701-50 – Firm material used for managing high energy impact with gasketing needs. Standard available thickness range from 0.30 mm to 12.7mm.

Download data sheet:PORON 4701-50 data sheet

PORON® 4701-60 – Very firm material used for energy management solutions for enclosure gasketing applications. Standard available thickness range from 0.53 mm to 12.7mm.

Download data sheet: PORON 4701-60 data sheet

Bisco® Silicone Sheet

BISCO® Cellular Silicones are ideal for sealing, cushioning, vibration isolation, and insulation. Their resistance to environmental extremes, mechanical resilience and safety features make them perfectly suited for critical applications in aviation equipment, communications and electrical enclosures, electronic products and components, industrial machinery and appliances. BISCO silicones also offer superb flame resistance and fire protection. Made in a wide range from ultra soft to extra firm, BISCO products serve as high-tech silicone sponges—with the enhanced sealing capabilities of traditional sponge rubber, but lighter in weight.

BISCO Silicones are the reliable choice for cushioning in solar panel constructions and in battery pad separators in hybrid electric vehicle design.

Products:

- BF-2000– Ultra-Soft Silicone Foam

- BF-1000– Extra-Soft Silicone Foam

- HT-870– Soft Silicone Foam

- HT-800– Medium Silicone Foam

- HT-820– Firm Silicone Foam

- HT-840– Extra-Firm Silicone Foam

- RS-700 – Specification Grade Silicone Sponge

BISCO® Silicones – Solid Silicones

BISCO® Solid Silicone materials are designed for high temperature/high pressure gasketing applications. They are available in a range of thicknesses and durometers to meet a variety of customer needs and requirements. Grades are also available with fiberglass reinforcement for added dimensional stability and with increased tear strength.

Products:

- HT-1200 series– General Purpose Silicone Rubber

- HT-6000 Series– Performance Solid Silicones

Neoprene Rubber

Neoprene rubber polychloroprene / CR has good aging characteristics in ozone and weather environments it is also resistant to both petroleum-based lubricants and to oxygen.

The combination of wide temperature range -40°C to 110°C and moderate cost, accounts for its desirability in many seal applications. CR is not effective to aromatic and mineral oils

The following grades are available from stock:

PR606J – Standard grade

PR606W – Fire resistant, UL94-VO

PR305B – Superior quality, meets European Railway norm – EN455545/2

EPDM Rubber

EPDM rubber is an elastomer which is characterized by wide range of applications. EPDM rubber is used in automotive weather-stripping and seals, glass-run channel, radiator, tubing, belts, electrical insulation, roofing membrane, rubber mechanical goods, thermoplastic, vulcanizates, motor oil additive, pond liner and electrical cable-jointing.

NBR/PVC blend

Nitrile Butadiene Rubber/PVC blend, is a thermal insulating sheets, anti-condensation, closed cell foam rubber with many excellent qualities.

Type 250 flexible insulating sheet is made with elastomeric foam. It has strong resistance to oils, chemicals, UV light, ozone and weathering. As NBR is blended with PVC, ageing resistance is improved, likewise, flame, ozone and petrol resistance are largely improved.

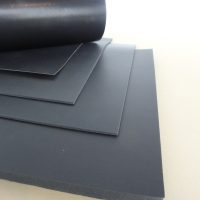

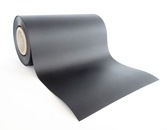

MVQ Silicone

MVQ Silicone is an elastomer based on methyl, vinyl and silicone. The ideal use of this material is in static seals especially where there is a need for high temperature resistance.In comparison with other rubbers, MVQ has a low mechanical characteristic and is therefore primarily used for the manufacture of non moving parts. It has excellent aging, weathering and ozone resistance. MVQ has an excellent temperature resistance ranging from -60° up to +230°C and short term up to 250°C.

More Information:

MVQ is typically used for the production of O-Rings and other seal parts. It is not recommended for dynamic situations due to poor abrasion resistance and high friction characteristics.

MVQ is often used as a sealing material in the chemical, pharmaceutical and food industry.

Typical Applications:

Electronics, Heating & Ventilating, Lighting, Automotive, Construction.

MVQ Silicone is available from Pronat in the below format:

| thickness | tolerance | width | roll length | standard roll area | weight | yield | roll weight |

| mm | .+/-mm | mm | M | M² | kg/M² | M²/kg | Kg |

| 1.5 | 0.2 | 1200 | 10 | 12 | 1.8 | 0.56 | 21.6 |

| 2.0 | 0.3 | 1200 | 10 | 12 | 2.4 | 0.42 | 28.8 |

| 3.0 | 0.3 | 1200 | 10 | 12 | 3.6 | 0.28 | 43.2 |

| 4.0 | 0.3 | 1200 | 10 | 12 | 4.8 | 0.21 | 57.6 |

| Grades: | GP60- Hardness: 60 Shore A GP40- Hardness: 40 Shore A |

||||||

| Availability: | White, black, translucent one side with adhesive surface |

||||||