-

PRONAT Electronics

-

PRONAT Aerospace

-

PRONAT Medical

-

Production Capabilities

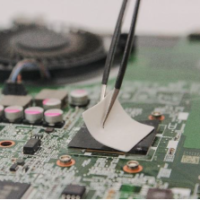

Thermal Gap Fillers

Gap pads or fillers provide an effective thermal interface between heat sinks and electronic devices where uneven surface topography , air gaps and rough surface textures are present. These filled silicone polymer sheets are used to provide thermal solutions when interface gaps are greater than 0.5mm. They are easy-to handle, re-workable and excellent for complicated die cut shapes. They offer good compression for stress relief and shock dampening.

Pronat offers a full range of thermally conductive materials as shown below. These materials have been selected for their excellent conductivity rating ( W/m-K) for each thickness sector, soft/hard parameters and consistent durability under stress.

Availability: Cut sheets and die-cut parts

Recommended Gap fillers available from stock in various thicknesses:

| Thickness | Hardness | Dielectric Strength | Thermal Conductivity | Material | |

| mm | Shore A | Kv/mm | W/m-K | ||

| GF-868G | 0.5 – 15 | 15 | 2 | 5.00 | silicone rubber |

| GF-866G | 0.8- 6.0 | 5±3 | 8 | 3.15 | silicone rubber |

| GF-866ER | 0.5-6.0 | 5±3 | 6 | 2.00 | silicone rubber fiber glass reinforced |

| GF-868B | 0.3- 6.0 | 15±3 | ˃5 | 3.00 | silicone rubber |

| GF-8620AR | 0.5-5.0 | 10±3 | 6 | 7.00 | silicone rubber |

Pronat stocks and converts gap fillers from world leading manufacturers for a wide range of electronic applications.

Some of our supply partners of thermal gap fillers include:

- Grow Rich

- Saint Gobain – ThermalCool grades

- Fujipoly – Sarcon grades

- Chomerics

- Bergquist

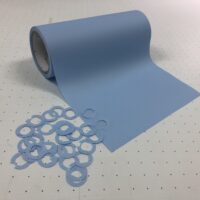

Thin Thermal Conductive Pads

These standard or fabric reinforced silicone polymer sheets are used to provide thermal management solutions where interface gaps are less than 0.50mm. These materials can be used for low cost thermal transfer requiring minimal thickness, high physical and mechanical characteristics. The fiberglass/silicone compound construction provides excellent cut through resistance, good thermal conductivity and excellent electrical insulation.

Availability: Cut sheets and die-cut parts.

Recommended insulators available from stock in various thicknesses:

| Colour | Thickness | Hardness | Dielectric Strength | Thermal Conductivity | Material | |

| mm | shore A | KV/mm | W/m-k | |||

| PRN78NFX1 | Grey | 0.23-5.0 | 70 | ˃10 | 1.0 | non- fiber silicone rubber sheet |

| PRN78NFX2 | Grey | 0.23-0.3 | 80 | ˃10 | 2.0 | non- fiber silicone rubber sheet |

| PRS300D | Green | 0.23 | 80 | ˃6 | 3.0 | silicone rubber fibre glass reinforced |

| PRS300F | White | 0.2 | 90 | ˃6 | 5.0 | silicone rubber fibre glass reinforced |

Some of our supply partners of thermal gap fillers include:

- Grow Rich

- Saint Gobain – ThermalCool grades

- Fujipoly – Sarcon grades

- Chomerics

- Bergquist

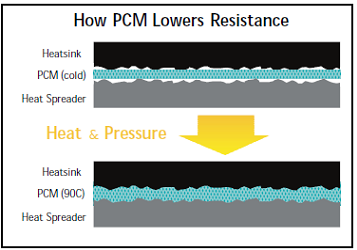

Thermal Phase Change

Thermal phase change materials are solid pads at room temperature that melt at preset operating temperatures above 50°C and provide complete wet-out of the interface, thereby eliminating any air gaps.

Typical change:

- Electronic modules for power devices power supplies.

- Electrical insulation

- Telecommunications

Typical Features:

- Type: silicone coated fabrics.

- Thickness: 0.1-0.2 mm

- Thermal conductivity: 3-8 W/m-k

- Temperature range: -30°C up to 125°C

Benefits:

- Very good conformability

- Available as die cut parts

Keratherm® Ceramic tape

KERATHERM® are highly flexible products made of thermally conductive and electrically insulating single or multi-component polymers, which are filled with ceramic or thermally conductive materials.

Keratherm® thermal interface materials ensures efficient cooling of the electronic components by connecting the heat source to the heat sink.

A mechanical reinforcement of Keratherm® by means of integrated glass fiber fabric or other materials offers the user a versatile product. Due to its flexibility and very good physical properties, extensive applications in electronics is possible.

Keratherm® is commonly used in conjunction with power electronics inautomotive applications such as batteries, electric powertrains, LED lighting, on-board chargers, sensors and much more.

- Keratherm® thermal conductive foils have a high thermal conductivity and have an electrically insulating effect.

- By using Keratherm® products, assembly problems such as smearing and assembly errors can be avoided.

- Compared to conventional heat conducting materials, Keratherm® products do not dry out in continuous use and therefore retain their good heat conducting properties for years.

- In contrast to discs made of mica, aluminum or polyamides, Keratherm® products can be used without thermal paste.

- Silicone-based Keratherm® facilitates component assembly due to its self-adhesive properties .

Commonly used grades of Keratherm®

Grades Substrate W/mK Properties 86/37 Heat conducting film 2.5 86/60 Heat conducting film 4.5 86/60 K Heat conducting film 4.5 with adhesive coating on one side 86/125 Ceramic filled film 1.5 single layer / adhesive on one side 86/128 Ceramic filled film 1.5 double layer / adhesive on one side 86/200 K Ceramic filled film 1 double layer / adhesive on one side 86/225 Ceramic filled film 2 single layer / both side strong self sticky 86/228 Ceramic filled film 2 double layer / one side strong self sticky 86/300 K Ceramic filled film 2 with adhesive coating on one side 86/320 Ceramic filled film 2.5 single layer / both side strong self sticky 86/325 Ceramic filled film 3 both sides lightly self sticky 86/525 Ceramic filled film 5.5 KL 90 Heat conducting film 1 adhesive tape PCM471 Phase Change Material (PCM) 4 filled hot-setting wax, not coated on aluminum U 90 Polyurethane film 6 Silicone free U281 Polyurethane film 2 silicone free

Properties

- Good insulation properties

- Thermally conductive

- Good compressibility

- Flexible

- Environmentally friendly

- RoHS compliant

Possible applications

- Powersupplies

- Automotive, motor controller

- LCD displays

- White goods

- Audio and video components

- Power converter

- LED lighting

Advantages

- Smooth surface

- Very good properties even with

- the lowest contact pressure

- Low hardness

- High self-adhesion without glue

- UL listing

Supply options

- one-sided adhesive coating

- cut sheet or die-cut parts

- glass fiber reinforcement

- silicon free thermal pads

Bergquist Super Conductive Pads

Thermal pads having exceptional thermal conductivity.

Typical Applications

Consumer electronics – Power supplies – Automotive electronics – LED, LCD and optical displays

Motor controls – power semiconductors batteries

|

TGP 18000SF |

thermal conductivity |

18 W/m-k |

|

TGP 40000SF |

thermal conductivity |

40 W/m-k |

Thermal Tapes & Adhesives Transfer Tapes

Thermally conductive pressure sensitive adhesive tapes provide solutions for difficult thermal management challenges. These products can be used in place of mechanical fasteners, provide excellent thermal coupling between components and heat sinks and can accommodate materials of different coefficients of thermal expansion with the compliant interface. All of the adhesives are flame retardant and are formulated for high performance adhesion while still being easily re-workable without damage to sensitive components.

Typical Applications:

Thermal tapes are used in place of mechanical fasteners to join heat sinks to computer processors, or to electrically isolate components of a power supply while still providing an excellent thermal conduction path.

Typical Features:

- Type: aluminum and copper foil, graphite paper, transfer adhesive tapes.

- Thickness: 0.11-0.3mm.

- Thermal conductivity: 0.4-2.6 W/m-k

- Temperature range: -60°C up to 260°C

Benefits: No need for mounting holes/screw to clamp, easy to apply.

Adhesive Transfer Tapes

Thermally conductive adhesive transfer tapes for applications requiring thin bonding with good thermal transfer

Typical Applications:

- CPU

- Flexible circuits

- Power transformer bonding to heat sinks or other cooling devices

Typical Features:

- Type: acrylic adhesive.

- Thickness: 0.13-0.50 mm

- Thermal conductivity: 0.4 – 0.6 W/m-k

- Temperature range: up to 120°C

Benefits:

- No need for mounting holes/screw to clamp

- Available as die-cut parts

- Easy-to handle

Pronat stocks world class thermal management materials

Pronat stocks world class thermal management materials.

Some of our supply partners of thermal gap fillers include:

- Grow Rich

- Saint Gobain – ThermalCool grades

- Fujipoly – Sarcon grades

- Chomerics

- Bergquist

- Kerafol ceramic material

Thermally Conductive Pastes & Gels

These materials are screened, stenciled or dispensed and require virtually no compressive force to conform under typical assembly pressures. Good surface wetting results in low interfacial resistance. Rather messy to apply for low volumes, for large quantities an automatic dispensing system is normally used. Clean removal is difficult.

Typical Applications:

- Standard dc/dc power converter and dc/ac inverter,

- High performance CPUs

- Between any heat generating semiconductor and heat sink

- Custom power modules

- Telecommunications and automotive electronics

Typical Features:

- Type: Silicone/non silicone

- Viscosity: 10,000-100,000 cps

- Thermal conductivity: 0.75 – 6.0 W/m-k

- Temperature range: -55°C up to 240°C

- Insulation strength: up to 15,000 Volt/mm

Benefits:

- Excellent surface wetting, can be implemented by automatic dispenser, low compressive force, cost effective.

Recommended greases & gels available from stock : TG-7801, GG6620-B, GG6620-C

Thermal Conductive Greases and Gel’s properties:

| Colour |

Thermal Conductivity (W /m-K) |

Thermal Impedance (°C-in2/W) |

Specific Gravity Bleed (%) | Bleed (%) | Viscosity (CPS) | Operation Temperture(°C) | |

| Environment | 200°C/24Hr | – | 25°C | 25°C | 200°C/24Hr | 25°C | – |

| TG-7801 | Grey | 3.8 | 0.087 | 2.5 | <0.05 | 76 | -50∼240°C |

| TG-7420 | White | 1.729 | 0.125 | 2.8 | <0.05 | 73 | -50∼240°C |

| TG-7700 | Silver | 1.93 | 0.12 | 2.5 | <0.05 | 68 | -50∼240°C |

| TG-7612 | Gold | 1.829 | 0.123 | 2.4 | <0.05 | 53 | -50∼240°C |

| GG6620-B | Light purple | 3.0 | <0.092 | >2.3 | <0.05 | No Flow | -30∼180°C |

Some of our supply partners of thermal gap fillers include:

- GrowRich

- Saint Gobain – ThermalCool grades

- Fujipoly – Sarcon grades

- Chomerics

- Bergquist