-

PRONAT Electronics

-

PRONAT Aerospace

-

PRONAT Medical

-

Production Capabilities

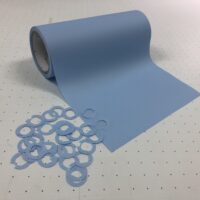

Keratherm® Ceramic tape

KERATHERM® are highly flexible products made of thermally conductive and electrically insulating single or multi-component polymers, which are filled with ceramic or thermally conductive materials.

Keratherm® thermal interface materials ensures efficient cooling of the electronic components by connecting the heat source to the heat sink.

A mechanical reinforcement of Keratherm® by means of integrated glass fiber fabric or other materials offers the user a versatile product. Due to its flexibility and very good physical properties, extensive applications in electronics is possible.

Keratherm® is commonly used in conjunction with power electronics inautomotive applications such as batteries, electric powertrains, LED lighting, on-board chargers, sensors and much more.

- Keratherm® thermal conductive foils have a high thermal conductivity and have an electrically insulating effect.

- By using Keratherm® products, assembly problems such as smearing and assembly errors can be avoided.

- Compared to conventional heat conducting materials, Keratherm® products do not dry out in continuous use and therefore retain their good heat conducting properties for years.

- In contrast to discs made of mica, aluminum or polyamides, Keratherm® products can be used without thermal paste.

- Silicone-based Keratherm® facilitates component assembly due to its self-adhesive properties .

Commonly used grades of Keratherm®

Grades Substrate W/mK Properties 86/37 Heat conducting film 2.5 86/60 Heat conducting film 4.5 86/60 K Heat conducting film 4.5 with adhesive coating on one side 86/125 Ceramic filled film 1.5 single layer / adhesive on one side 86/128 Ceramic filled film 1.5 double layer / adhesive on one side 86/200 K Ceramic filled film 1 double layer / adhesive on one side 86/225 Ceramic filled film 2 single layer / both side strong self sticky 86/228 Ceramic filled film 2 double layer / one side strong self sticky 86/300 K Ceramic filled film 2 with adhesive coating on one side 86/320 Ceramic filled film 2.5 single layer / both side strong self sticky 86/325 Ceramic filled film 3 both sides lightly self sticky 86/525 Ceramic filled film 5.5 KL 90 Heat conducting film 1 adhesive tape PCM471 Phase Change Material (PCM) 4 filled hot-setting wax, not coated on aluminum U 90 Polyurethane film 6 Silicone free U281 Polyurethane film 2 silicone free

Properties

- Good insulation properties

- Thermally conductive

- Good compressibility

- Flexible

- Environmentally friendly

- RoHS compliant

Possible applications

- Powersupplies

- Automotive, motor controller

- LCD displays

- White goods

- Audio and video components

- Power converter

- LED lighting

Advantages

- Smooth surface

- Very good properties even with

- the lowest contact pressure

- Low hardness

- High self-adhesion without glue

- UL listing

Supply options

- one-sided adhesive coating

- cut sheet or die-cut parts

- glass fiber reinforcement

- silicon free thermal pads